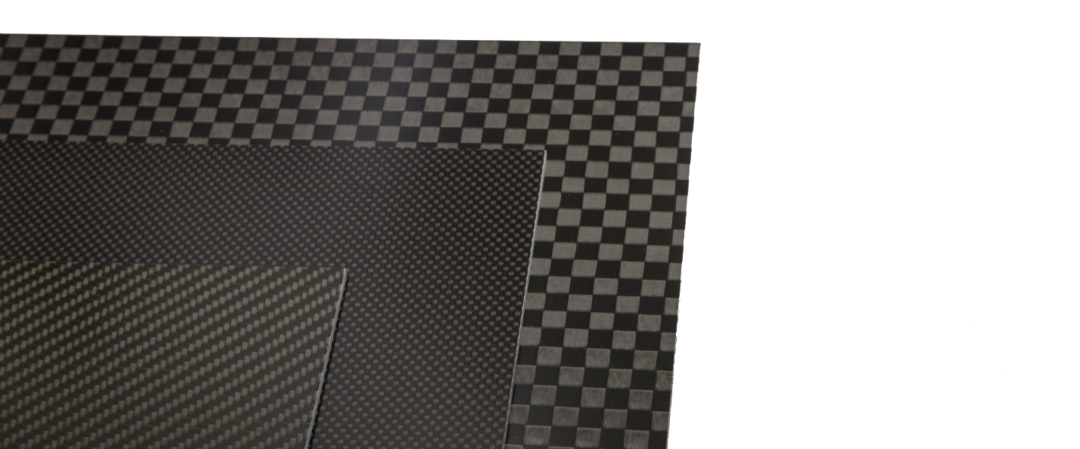

Carbon Fiber Weaves: What they are and why to use them

If you have ever wondered why one piece of carbon fiber might look different from another piece of carbon fiber, you’re not alone. Carbon fiber comes in many different weaves and each one serves a different purpose, and it isn’t just cosmetic.

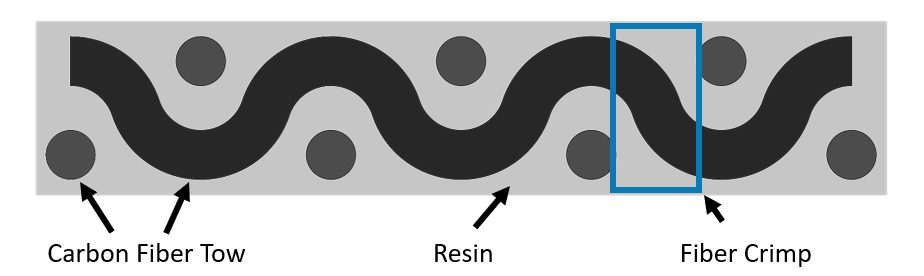

Carbon fibers are made from precursors such as polyacrylonitrile (PAN) and rayon. The precursor fibers are chemically treated, heated and stretched, then carbonized, to create high-strength fibers. These fibers, or filaments, are then bundled together in tows which are identified by the number of carbon filaments they contain. Common tow ratings are 3k, 6k, 12k and 15k. The “k” refers to a thousand, so a 3k tow is made of 3,000 carbon filaments. A standard 3k tow is typically .125” wide, so that is a lot of fiber packed into a small space. A 6k tow has 6,000 carbon filaments, a 12k has 12,000 filaments, and so on. This large number of high-strength fibers bundled together is what makes carbon fiber such a strong material.

Woven Carbon Fiber

Carbon fiber typically comes in the form of a woven fabric, which makes it easier to work with and can give additional structural strength depending on the application. Because of this there are many different weaves used for carbon fiber fabric. The most common are Plain, Twill and Harness Satin, and we will go into more detail for each.

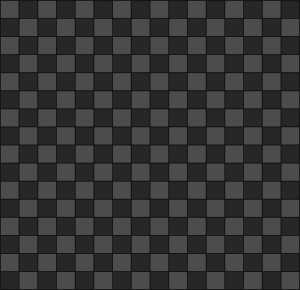

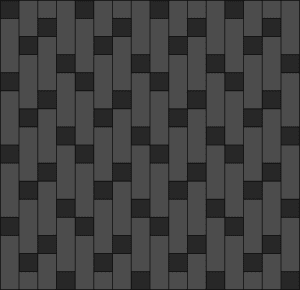

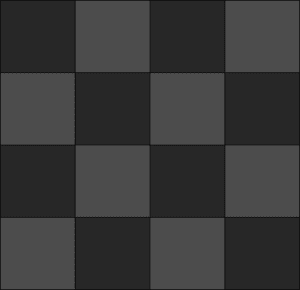

Plain Weave

A plain weave carbon fiber sheet looks symmetrical with a small checkerboard style appearance. In this weave the tows are woven in an over/under pattern. The short space between interlaces give the plain weave a high level of stability. Fabrics stability is the ability for a fabric to maintain its weave angle and fiber orientation. Due to this high level of stability, plain is not well suited for layups with complex contours, it will not be as pliable as some of the other weaves. Generally, plain weave fabrics are suited for flat sheets, tubes and 2D curves.

One drawback to this weave pattern is the harsh crimp (the angle the fiber makes when woven, see below) in the tows due to the short distance between interlaces. The harsh crimp can create stress concentrations which can weaken the part over time.

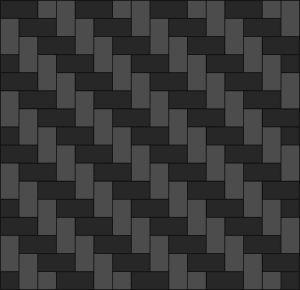

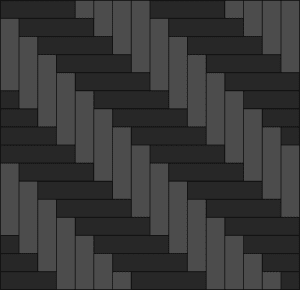

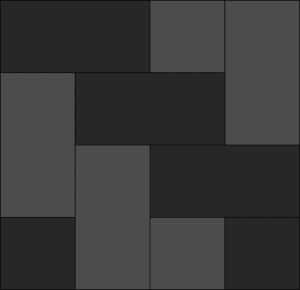

Twill Weave

Twill serves as a bridge between a plain weave and the satin weaves we will discuss next. Twill has good pliability and can form to complex contours, and it is better at maintaining its fabric stability than a harness satin weave, but not as good as plain weave. If you follow a tow strand in a twill weave it passes over a set number of tows and then under the same number of tows. The over/under pattern creates a diagonal arrowhead look, known as a “twill line”. The longer distance between tow interlaces means fewer crimps compared to a plain weave and less potential stress concentrations.

2×2 Twill

4×4 Twill

2×2 Twill is likely the most recognizable carbon fiber weave in the industry. It is used in many cosmetic and decorative applications, but also has great functionality, it has both moderate formability and moderate stability. As the 2×2 name implies, each tow will pass over 2 tows then under two tows. Similarly, 4×4 Twill will pass over 4 tows then under 4 tows. It has slightly more formability that 2×2 Twill, since the weave is not as tight, but it will also have less stability.

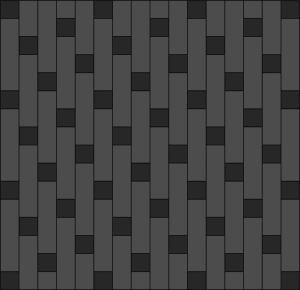

Harness Satin Weaves

The satin weave was designed thousands of years ago for making silk fabrics with excellent draping qualities, while also looking smooth and seamless. For composites, this drapability means it can easily form and wrap around complex contours. Because the fabric is so formable, it, expectantly, has low stability. Common harness satin weaves are 4 harness satin (4HS), 5 harness satin (5HS) and 8 harness satin (8HS). As you increase the number of the satin weave, formability will increase and fabric stability will decrease.

4HS

5HS

8HS

The number in the Harness Satin names indicates the total number of tows passed over then under. For 4HS, it will pass over 3 tows then under 1. For 5HS, it will pass over 4 then under 1, and 8HS will pass over 7 and under 1.

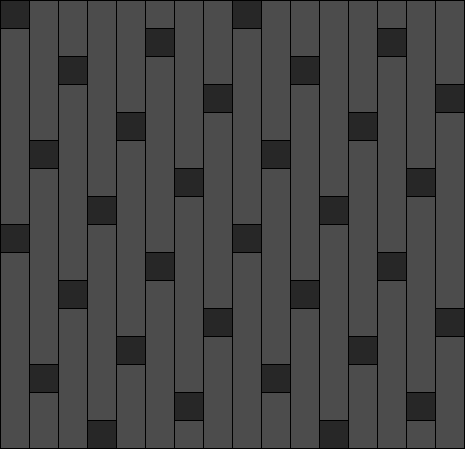

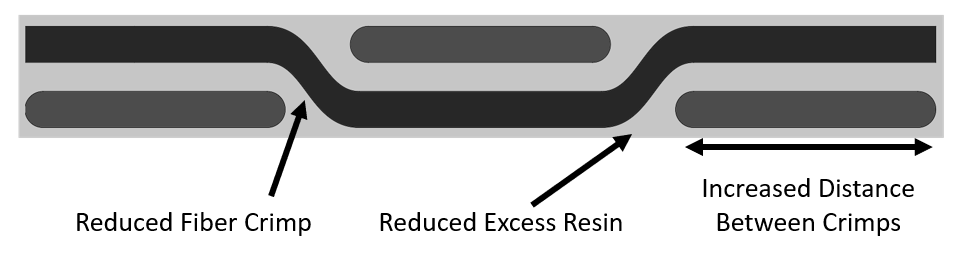

Spread Tow vs. Standard Tow

Spread tow material can be a good compromise between using uni-directional material and standard woven material. As a fiber tow weaves up and down to create a fabric, the strength is reduced due to the crimp in the tow. As you increase the number of filaments in a standard tow, from 3k to 6k for example, the tow becomes bigger (thicker) and the crimp angle becomes harsher. One way to avoid this is to spread the filaments out into a wider tow, this is called a spread tow and there are a couple of benefits gained by doing this.

The spread tow offers a smaller crimp angle than a standard tow weave and can decrease the crossover defects by increasing the smoothness. A lower crimp angle will result in higher strength. Spread tow material is also easier to work with than uni-directional material and still has reasonably good fiber pull up prevention.

Spread Tow Plain Weave

Spread Tow Twill Weave

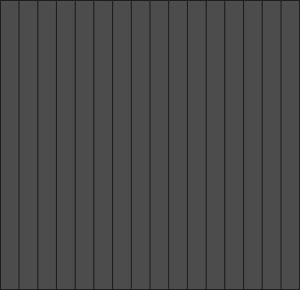

Uni-Directional

As the name implies, uni, meaning one, all of the fibers are oriented in the same direction. This gives uni-directional (UD) fabric some high strength benefits. UD fabric is not woven, there aren’t any interlacing fibers with crimping that can weaken the structure. Rather, there are continuous fibers that increase the strength and stiffness. Another benefit is the ability to tailor the layup with better control for performance characteristics. A bicycles frame is a good example of how UD fabric can be used to tune the performance. The frame must be stiff and rigid in the bottom bracket area to transfer the rider’s power to the wheels, but the frame also needs to have some compliance and flex to not beat up the rider. With UD material you can pick the precise direction of the fibers to get the strength you need.

One major drawback with UD though is its workability. UD tends to fall apart quite easily during the layup process since it has no interlaced fibers to hold it together. If the fibers are placed incorrectly it can be almost impossible to correctly reorient them all again. Machining parts made with UD fabric can also cause issues. If there is any fiber pull up where the features were cut, those loose fibers can pull up all the way across the part. Typically, if UD material is chosen for a layup, a layer of woven material is used for the first and last layer to assist with machineability and part durability. This is what is done for hobbyist drone frames all the way up to production rocket parts. If you enjoyed this post or have any additional questions, please leave a comment below. Sources and Reference Sites: https://store.acpsales.com/products/3495/woven-fabric-style-guide

I like this site because so much useful stuff on here : D.

Hi, I would like to know what carbon fibre material is used in Carbon fibre eclectropolishibg brushes. Used for electropolishing stainless steel welds. Is the strand thickness the same as those used in composite materials. I have been using standard 12k unidirectional carbon fibre which I bundle up and insert into a copper connector. It works well but doesn’t seem to last as long as those imported from overseas.

Would appreciate and advice.

Regards

John C

I am not familiar with the different fibers used for electropolishing brushes. From a glance at a couple of different brushes, it appears to be the same tow that is used to weave carbon fiber cloth in the standard fabrics you can find.

Some great wisdom here, thx. Question…repairing a cracked TT on my road frame, what would be best weave(s) to use? Thx

Something with a tighter weave would be best. Probably a 3k plain weave, but a twill should also work

Something with a tighter weave would be best. Probably a 3k plain weave, but a twill should also work.

Some great information but I don’t understand what the term “stability” refers to.

Hi Richard, Fabrics stability refers to the ability of a fabric to maintain its weave angle and fiber orientation when it moves and drapes over 3D geometry. When you lay a woven fabric flat, the fibers in that weave will remain perpendicular to each other. As you drape a weave over a contoured surface the fibers will have to shift their angle to lay against the surface. Fabrics that drape better allow the fibers to move relative to one another more easily. As you push the fabric into more complex 3D geometries the woven fibers move further away from being perpendicular. Stability in this case is the resistance a fabric has to the crossing fibers shifting away from being perpendicular.

good information

Well done. But can you address the pros and cons of using the various weaves and bundles a little more please. For example, using 3K versus 6K and also for UNI, the advantages of using stitched cloth compared to woven (straighter tows) etc .. all related to what gives the best strength performance. Cosmetic aspects interest me less as I always over paint for more UV resistance to the epoxy that is critical strength-wise. Thanks,

In most cases, the thickness of the tow, 3k, 6k, or 12k, etc. has to do with manufacturing. If you are trying to create a thin laminate with specific fiber properties, say quasi-isotropic, then you may need to use a thinner material to balance your layup and maintain a specific thickness target. You would use a higher filament count fiber when you want to build up a large thickness as quickly as possible and reduce the layup cost. There are almost indistinguishable differences in performance between different filament counts, which depend on the fiber type and can typically be found on the fiber manufacturer’s datasheet.

Great no nonsense information.

Great educational document!

Question-The Boeing 777 has Carbon fiber floor beams. The use of CF composites proceeded the 787 by many years and these floor beams on the 777 have stood the test of time with no issues or fatigue. For the application of a carbon fiber “floor beam” spanning 200 inches, would you have any idea what weave would have been used in the pioneering days of such design and use that dates back to mid 1990 with design, development and test a few years prior.

Great info.. I am a 25y aviation composite and structure instructor. It’s easy to understand for others.

very informative and helpful.

very helpful

Awesome info! First time I’ve been able to understand the relationship between the weave , the twill,and the harness! I love it!

Great article

Thanks for this. Great introduction to carbon fiber sheets and nice replies to the questions & comments. Very helpful.

I want to add a single layer of carbon fiber (flat surface) for cosmetic purposes. Is there a formula for the weight I will be adding? Obviously I can calculate the fabric weight per yard but what is the resin / epoxy weight to fill the weave to a smooth surface?

Typically you will get a good cosmetic finish with ~40-45% resin content. So if you have the weight of the fabric you want to use, multiply that by .667 to get the resin weight required.

unidirectional fibers offer the finest stiffness to weight ratio. But they’re brittle – woven carbon is more common – so it copes with impact better and is easier to mold, typically at complex

Great information thank you, really helping me understand the different properties.

A standard 3k tow is typically .125” wide, so that is a lot of fiber packed into a small space. A 6k tow has 6,000 carbon filaments, a 12k has 12,000 filaments, and so on. This large number of high-strength fibers bundled together is what makes carbon fiber such a strong material.

Thanks for for sharing this knowledge, has cleared a lot of doubts in my mind. A quick question ….how could I manufacture a circular tube using carbon fibre that can hold a high amount of internal pressure (around 300bars) ?

coat first. Carbon fiber components from an original equipment manufacturer are clear coated. The carbon weave is protected against fading by a clear coat. If you’re sealing your paint with something

What would be better for a ballistic test if I use MR70 as plain weave or 5HS and if not how would it effect in my impacts?

What’s about wave penetration.

From an engineer in the aerospace industry that has worked with composites, this was an excellent explanation!

Many carbon fiber pickleball paddles out there. I have tried two below, and would like to know if I want a rough surface and enough power, what materials should I look for in a paddle? How is Toray-700 carbon fiber compares to 3K/18K for roughness and power ?

Rough surface that give good control, but no power.

Paddle Face Finish: 3K Woven Carbon Fiber.

Ribbed Core Material: T-700 Carbon Fiber

Smoother face, but more power.

Face: 18K plain weave carbon fiber.

Core: polypropylene honeycomb

Thank You !

Many different factors drive the performance of pickleball paddles.

The surface finish is unrelated to the fiber type. Surface finish is driven by either a release film imprinting a texture into the resin surface during the panel manufacturing process or a coating used on the carbon fiber panel after it has been assembled.

Fiber type will contribute to the stiffness of the paddle, but the stiffness is also driven by the core material, the thickness of the carbon panel, the thickness of the core, and other materials used in the construction.

Hello Ryan,

In your opinion, what would be the best combination for a softball bat? Bats obviously take a beating but trying to get both performance and durability seems to be the holy grail. We usually find one without the other. Is it the weave, the layup, or a combination of both?

I know that some of the best carbon fiber softball bats are filament wound. Check out the Pure Sports bats. They make an awesome product.

Hi, is the 2×2 twill weave the same as the ‘bidirectional’ carbon fiber used to strengthen/repair concrete basement walls?

is the 2×2 twill weave the same as the ‘bidirectional’ carbon fiber used to strengthen/repair concrete basement walls?

what temperature will this material go up to?

the temperature each material is rated for depends on the resin system used. Standard panels at Elevated Materials have a Tg of 250F and can be made to have a Tg of 350F upone request.

Clear and very useful information, well written and with good diagrams, thanks. As a photographer and keen cyclist, I have often wondered what influenced the choice of different weaves for different components.

Many tripods use angled waves on the legs. Is this a proprietary thing, or generally available, like the other fabrics? I am guessing it might be very specific to each application. What are the pros and cons of angled weaves? I imagine it is used where tensile strength and rigidity is more important than torsional.

Thanks for this very useful information. I remain confused about drapability versus stability in the December 26 2020 exchange. I assume the property of drapability is the ability for a sheet of woven material to conform to a given shape. Higher drapability should mean less force needs to be applied for the sheet to take on the shape. Also, there should be little damage to the fibers if highly drapeable.

It would seem to me that stability is the property of a weave maintaining a given shape after it has been shaped.

1) Is that correct?

2) If so, how does this stability relate to “the resistance a fabric has to the crossing fibers shifting away from being perpendicular”

3) If this is not how to think about stability, what is the “big picture, macroscopic” definition of stability?

4) Does good drapability mean high stability or low stability?

We constider the weave stability the ability for the weave to maintain a 0 and 90 degree fiber orientation as it is draped over complex shapes. To clarify, this is not relevant for cured sheets, becuase the resin solidifies and locks the fibers in. Once cured into sheet the material is no longer formable. This page is intended to discuss the characteristis of uncured material.

The terms warp and weft are used to describe the two basic directions in weaving yarn into textile fabrics. The vertical warp yarns are wound around the roll and the horizontal weft is woven back and forth across the roll. When a roll woven carbon fiber is unspooled the generally the warp and weft fibers are perpendicular to each other, at 0 deg down the length of the roll, and 90 deg across the width of the roll.

Often when draping fabric over complex shapes the angle between these fibers will change to compensate for the fabric having to distort to fit against a surface. If you are expecting the fibers in a woven fabric to be aligned in a certain direction after being laid against a 3D surface for stifness purposes, it is important to consider that the wrap and weft fibers in a given woven layer will likely not remain perpendicular.

Good drapability generally means low stability becuase the drapability allows the fibers to shift in their weave as they conform to a complex shape. Stable fabics have difficulty conforming to complex 3D surfaces becuase the fibers do not shift around as easily.