About Us – Mission To Reduce Waste

Our “Space Grade” Carbon Fiber Material

Rockets and space craft experience extreme loads and forces when launched into space. In order to survive this they must be constructed with strong and durable materials. Another important factor for rockets is weight, that is why carbon fiber is the go-to material for the space industry.

All of our products are made with the same carbon fiber material used in the commercial space flight industry. That is why we say our material is “Space Grade,” it has literally been designed for space travel.

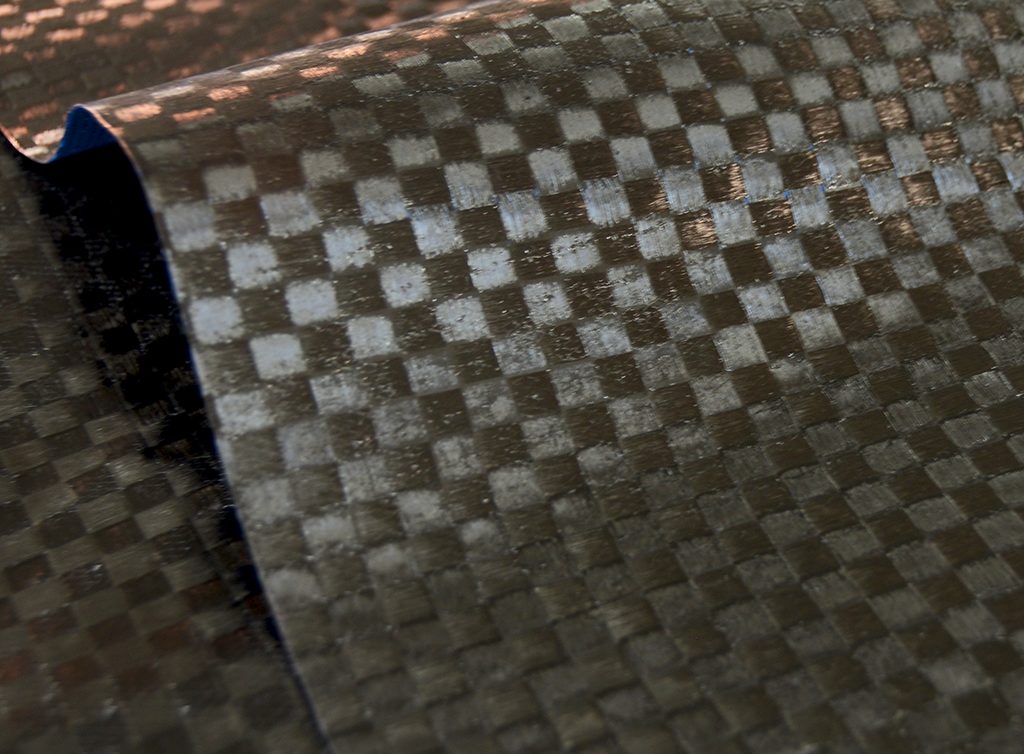

The carbon fiber material we use is resin impregnated woven cloth that is commonly referred to as “pre-preg.” It is made with high quality carbon fibers combined with space industry defined resin systems, which separates our material from the rest. Many companies will cut cost with lower quality fibers or inferior resin systems that aren’t as durable.

We use heated compression molding to cure the pre-preg material into flat sheets, which we sell on our site. We offer a wide selection of flat sheet with many choices for size and thickness; custom sizes and cuts are also available. We also offer services to support end-to-end part manufacturing, from product design through fulfillment. Click the links below to learn more.

Mission: Zero Waste

Our company was started with a singular mission, to eliminate the carbon fiber waste coming out of the commercial aerospace and space flight industries. Over 10 million pounds of carbon fiber waste and scrap was produced last year. Some of it is incinerated but the majority is sent to the landfill. As we mention on our Materials page, this stuff is designed to survive the harsh conditions of space travel, which means it is not biodegradable, it will sit in the landfills and continue to pile up. With more, and larger, planes and rockets being built, this problem will only get worse.

Our Founder, Ryan Olliges, identified this issue while studying Aerospace Engineering at the University of Southern California (USC), and he decided to do something about it and launched 121C Inc. The goal of 121C was to show that this waste material could be “upcycled” into strong and durable products. This resulted in the creation of 121C Boards, a line of 100% carbon fiber skate decks. With three successful Kickstarter campaigns and over 2000 boards sold, they knew there was a market for high quality, environmentally friendly, carbon fiber products.

Over the last few years 121C has been approached by various companies to help them make parts out of carbon fiber. We saw this as an opportunity to grow the business beyond skateboards. It would also allow us to collect, and use, more of the waste carbon fiber that is being sent to the landfill. We decided to create a new brand to focus on these new markets, that is how Elevated Materials was born. While we offer many products and services, our mission remains the same, to eliminate carbon fiber waste. Since we started we have diverted close to 200,000 pounds of waste material, and we aren’t stopping any time soon. So join us on this mission of achieving Zero Waste today.

Our Team

Founder, President

Ryan Olliges

Ryan is an Aerospace Engineering graduate from the University of Southern California. While working in the Rocket Propulsion Lab he realized how much unused carbon fiber is sent to the landfill during the manufacture of rockets and spacecraft. As someone who loves the outdoors and the environment, Ryan immediately set about finding a solution to this problem.

Co-Founder, VP, Tech Development

Jaysen Harris

Jaysen has many years of entrepreneurial experience in several startups. He is experienced in implementation systems throughout organizations large and small, including several major projects in the IT Field. Jaysen is also experienced in web, ecommerce and app development.

Our Advisors

Michael López-Alegría

Industry Expert

Mike LA is one of America’s most experienced astronauts. He flew on numerous Space Shuttle missions and served as International Space Station commander. He also served as President of the Commercial Spaceflight Federation. As a product spokesperson and industry liaison, Mike’s achievements inspire the whole team to reach for the stars

Paul Olliges

Production

Paul has many years of experience with composites in the marine industry. He has worked in design and manufacturing for Bayliner and Glacier Bay Catamarans, and is currently General Manager at Sea-Dog Line. He has a BFA in industrial design & MBA from the University of Washington

Steven Nutt, PhD

Research & Development

Steven is an M.C. Gill Professor of Chemical Engineering & Materials Science at the Viterbi School of Engineering at USC. He has his BS, MS and PhD from the University of Virginia having done extensive research on carbon fiber. He has be Director of the Composites Lab at USC and is well connected with the traditional aerospace firms

Adrian Stern, CPA, CFE, CFF, CRFA, CICA

Finance

Adrian is an adjunct professor at the Marshall School of Business at USC. He is a founding partner of the firm Clumeck, Stern, Schenkelberg & Getzoff, a certified Forensic Accountant and Chairman of the California Center for Public Health Advocacy.