What are Forged Carbon Fiber Blocks?

For use as brackets or components, carbon fiber has several properties that give it an advantage over other materials. Carbon is lightweight corrosion resistant and stiff. Blocks can easily be tapped and milled to any geometry required. Different carbon fiber blocks can have different appearances. Each style has properties that give a unique benefit.

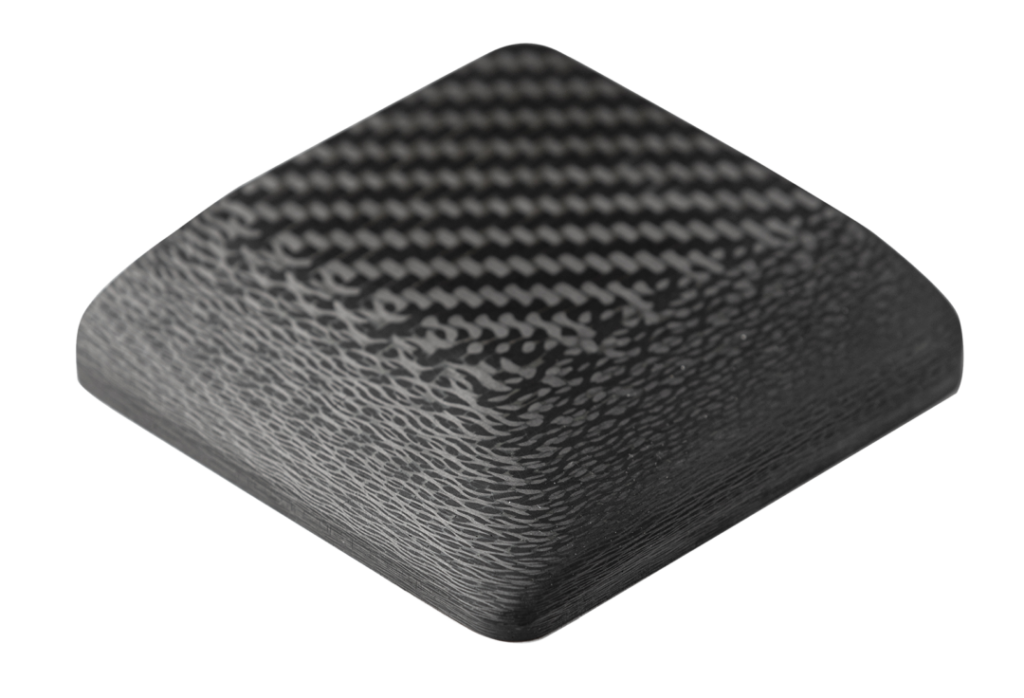

Forged Carbon Fiber

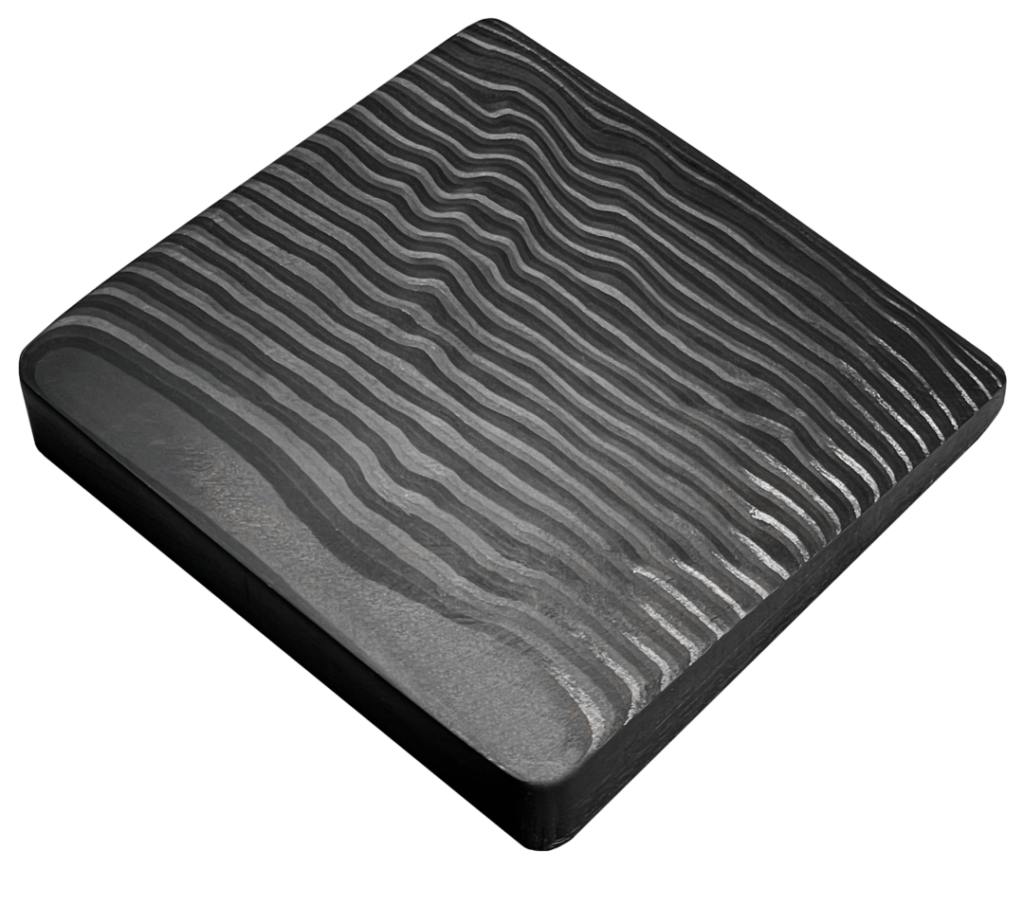

Marbled Carbon Fiber

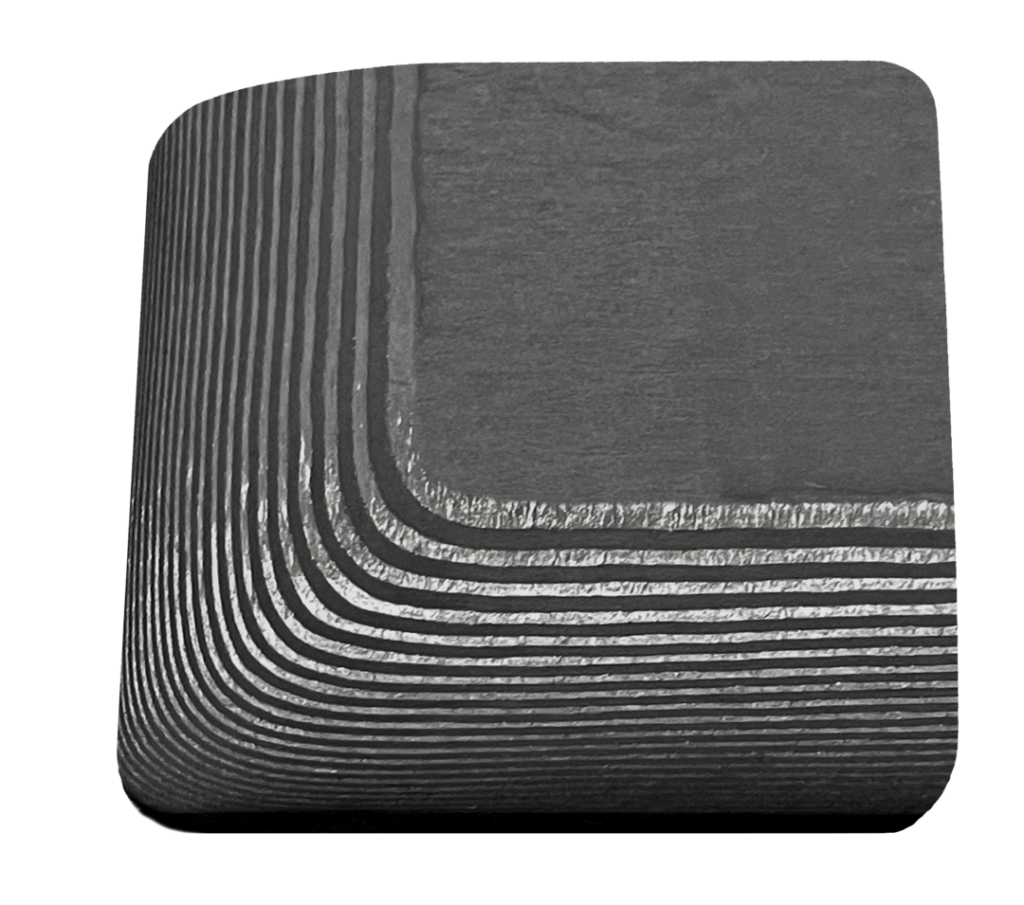

Damascus Carbon Fiber

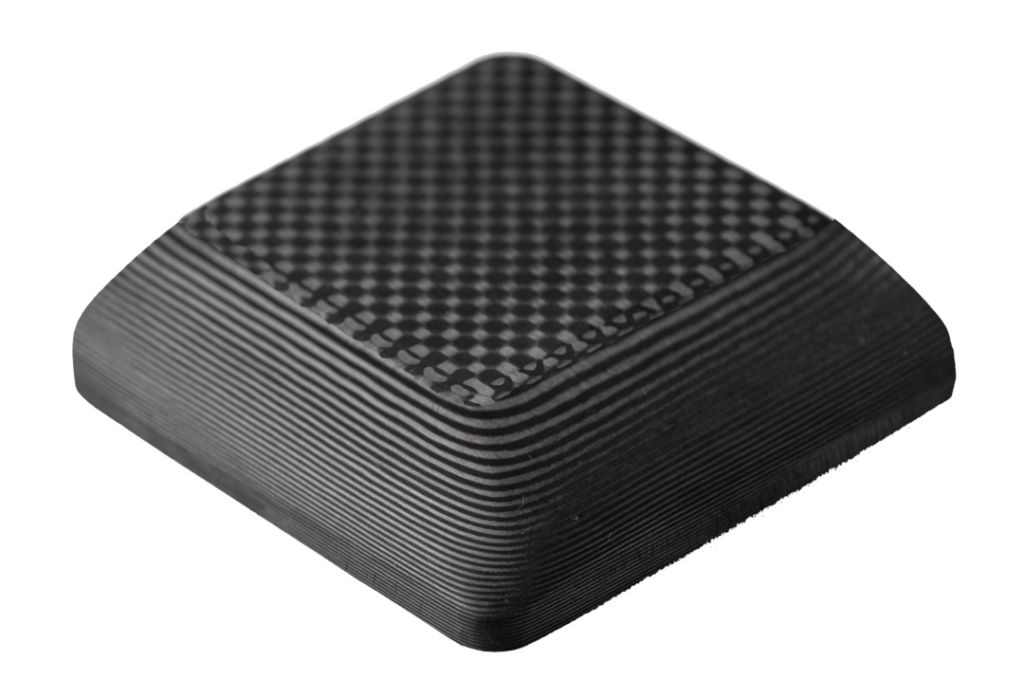

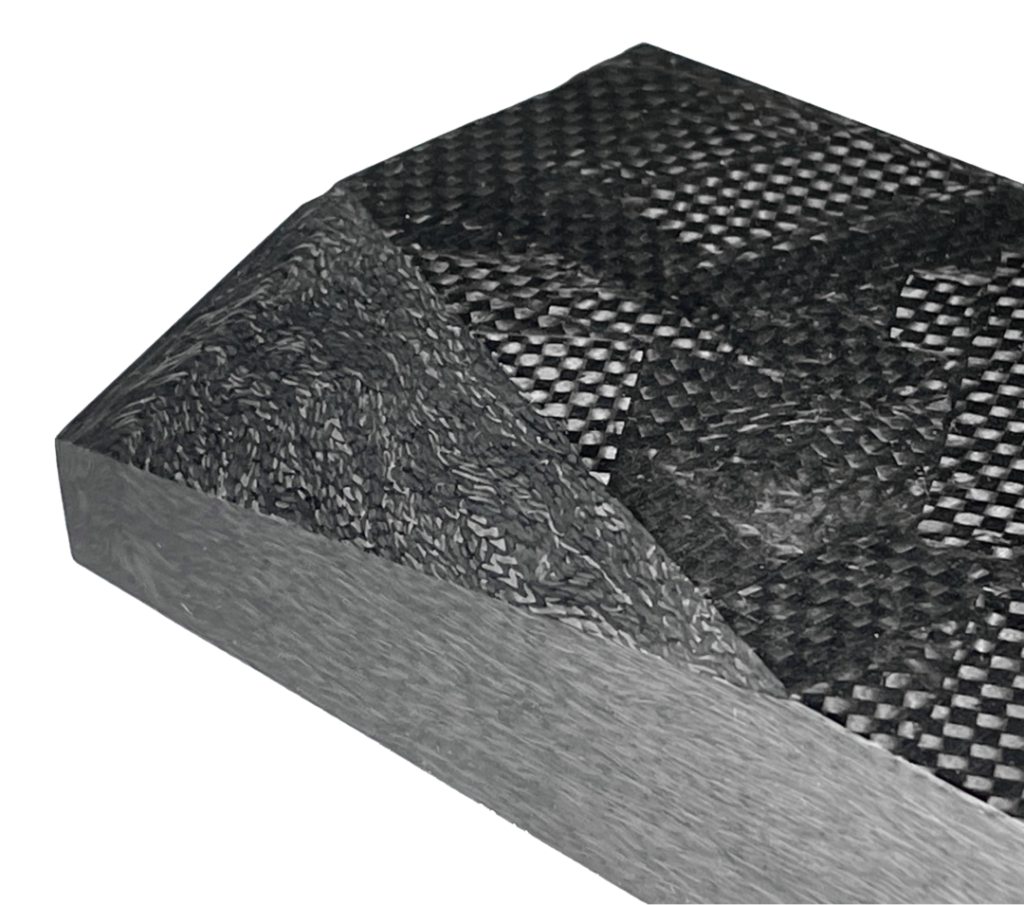

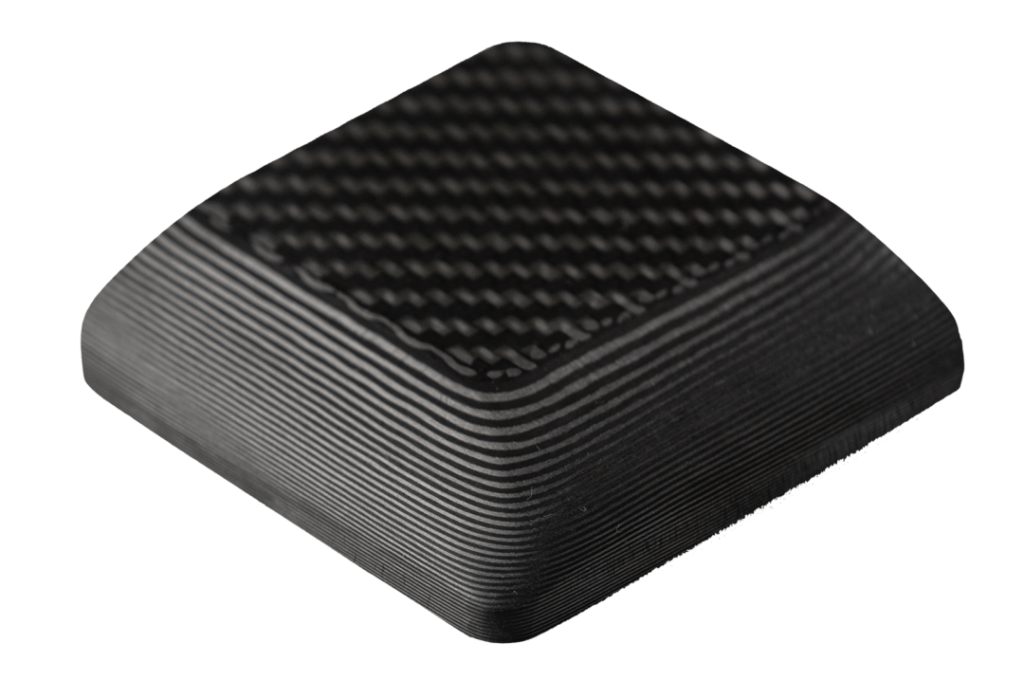

Forged Carbon Fiber Block

Forged carbon fiber is the most machinable of the carbon fiber blocks made at Elevated Materials. These blocks are made using woven carbon fiber. Because the fibers are interlocked and randomly oriented there is very little risk of fiber blowout during machining and often these parts have the best finishes directly off the machine.

While these blocks are press manufactured and many of the fibers are oriented in the x and y plane, there are also fibers oriented in the z-direction. Though this is not a 3D weave, fibers aligned in the z-axis make the billets more isotropic than standard composite laminates.

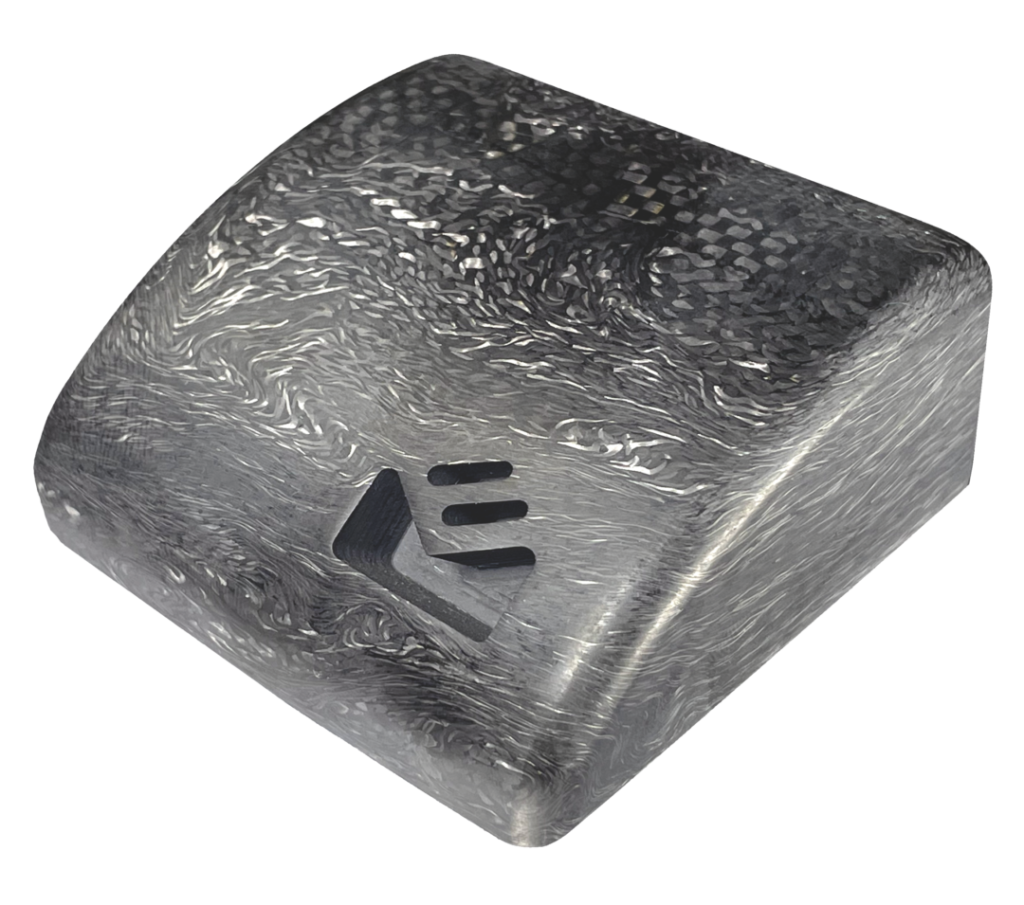

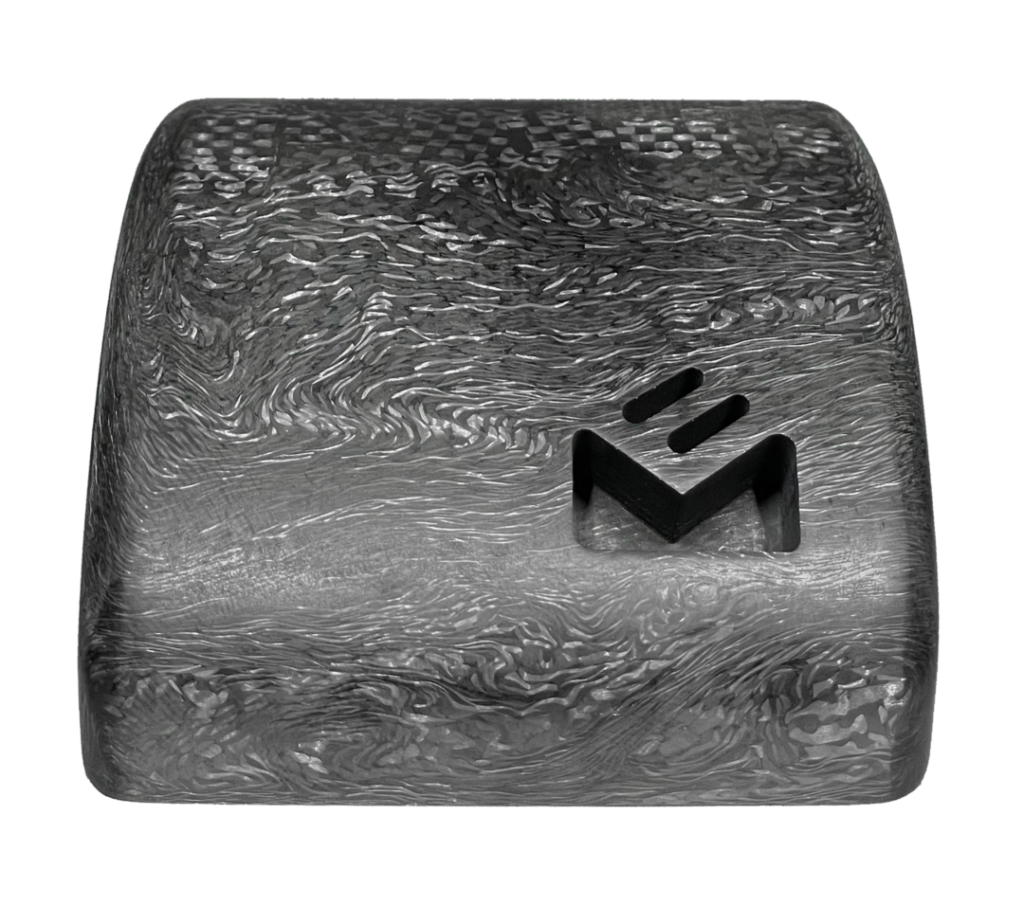

Marbled Carbon Fiber

Marbled carbon fiber blocks are similar to the forged carbon blocks, but made with unidirectional material instead of woven material. Each marbled carbon fiber block has a unique fiber orientation giving every part a special appearance.

Because of the process used to make the marbled carbon blocks, more fibers end up oriented in the Z direction. Because the fibers are all unidirectional, as opposed to being interlocked in woven material, cutting threads is still possible, but not as easy as the woven forged carbon blocks.

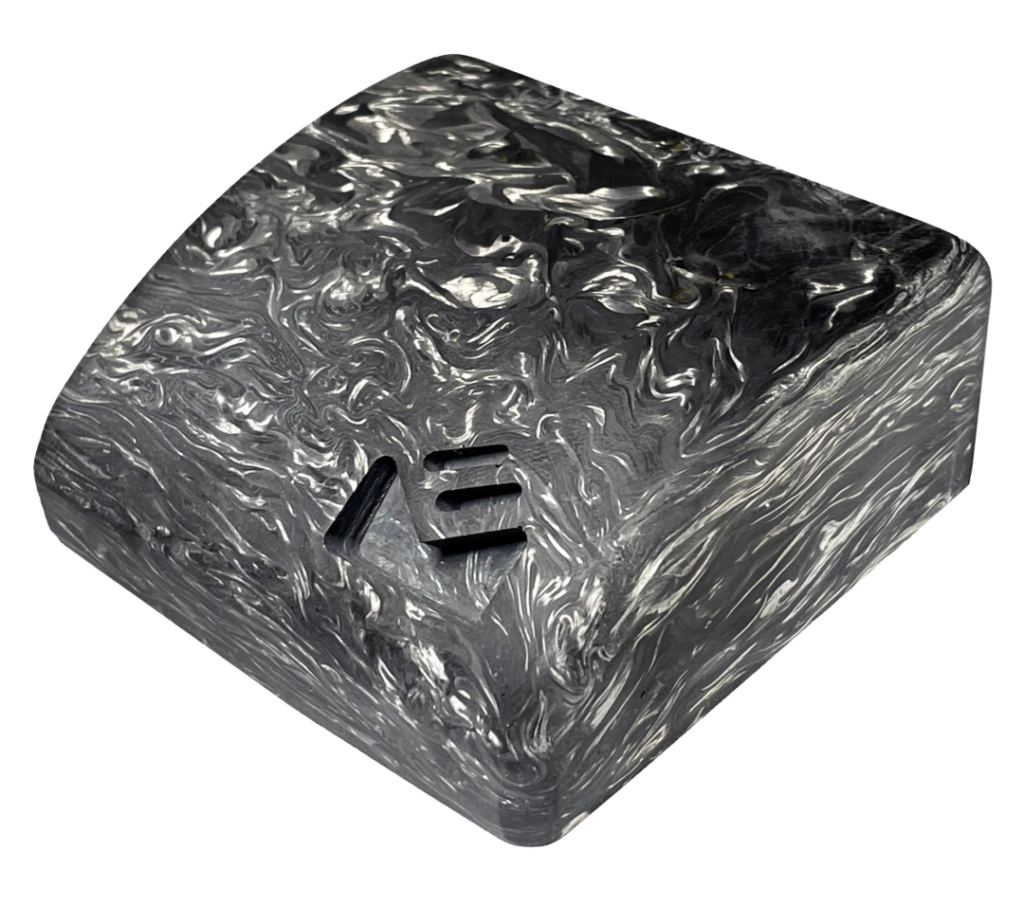

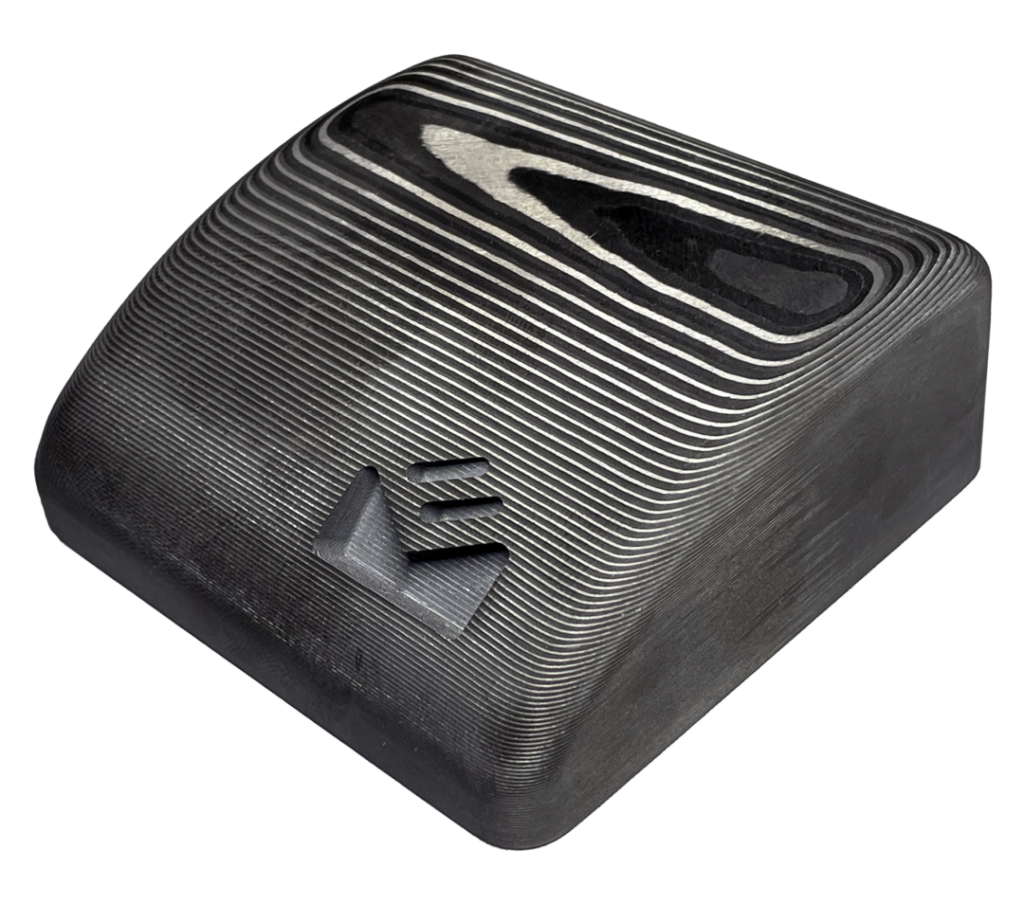

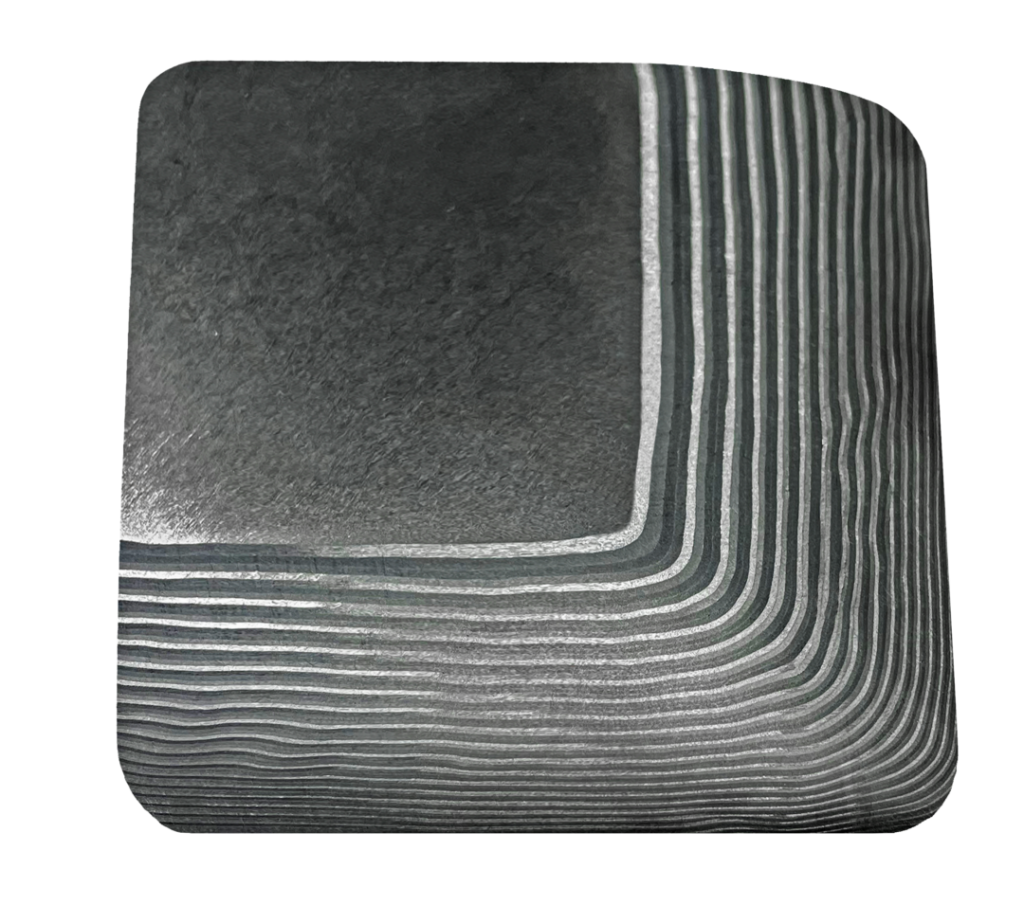

Damascus Carbon Fiber

The Damascus uni blocks are standard uni directional laminated made thick enough that they can be machined into parts on a milling machine. Like the other carbon fiber blocks, parts made with these can have holes, features, and threads in any orientation.

The blocks can be made from unidirectional fabrics of different thicknesses and the fabrics can be laid at different angles, giving the blocks a unique look. The weave orientation determines the way light reflects on each layer and the look of the material. The two most standard layup procedures are orienting all of the fiber layers in alternating 0 and 90 deg directions and orienting the fibers in 0, +45, 90, and -45 deg, referred to as quasi-isotropic. Each fiber orientation reflects light in a slightly different way, so the more fiber orientations, the more unique layers appear to be present.

The primary structural benefit of Damascus uni material is that it maintains the strength of a standard carbon fiber laminate in the x and y directions. The properties can be characterized and kept consistent with a higher degree of certainty. Properties like CTE can be controlled by alternating material choices. Even with consistency, each part made from these blocks has an individual look.

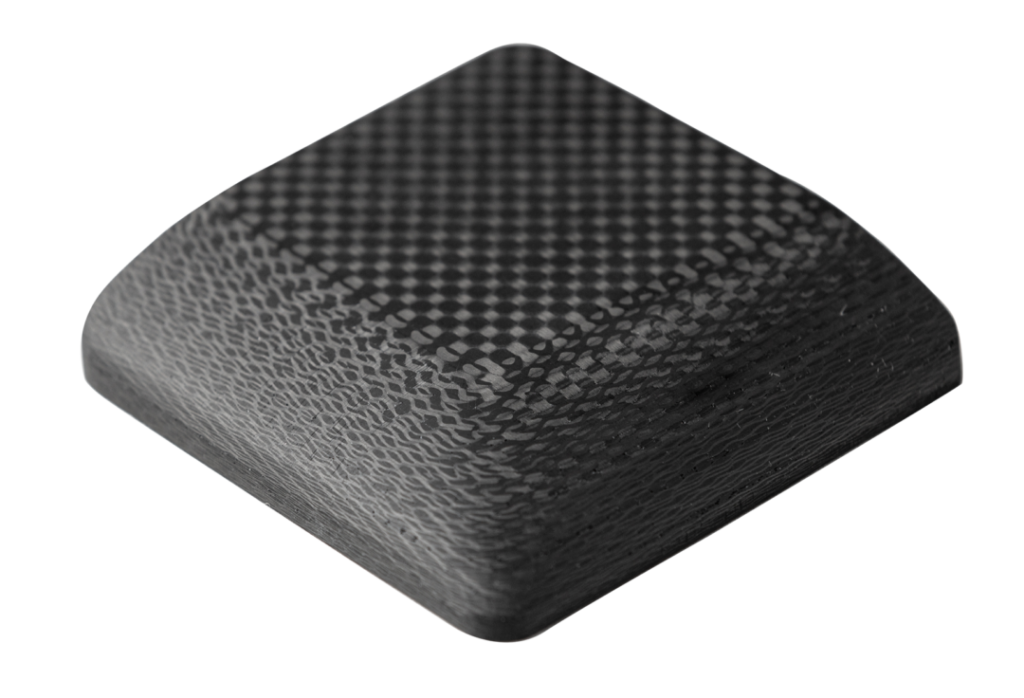

Other Carbon Fiber Blocks

In addition to the other blocks listed above, Elevated Materials manufactures carbon fiber billets with different materials that provide different aesthetics and properties. Reach out to us today to learn more and get a quote for carbon fiber blocks, or to have your parts machined from them.

All Twill Weave Laminate

All Plain Weave Laminate

Twill Weave With Uni Core

Plain Weave With Uni Core