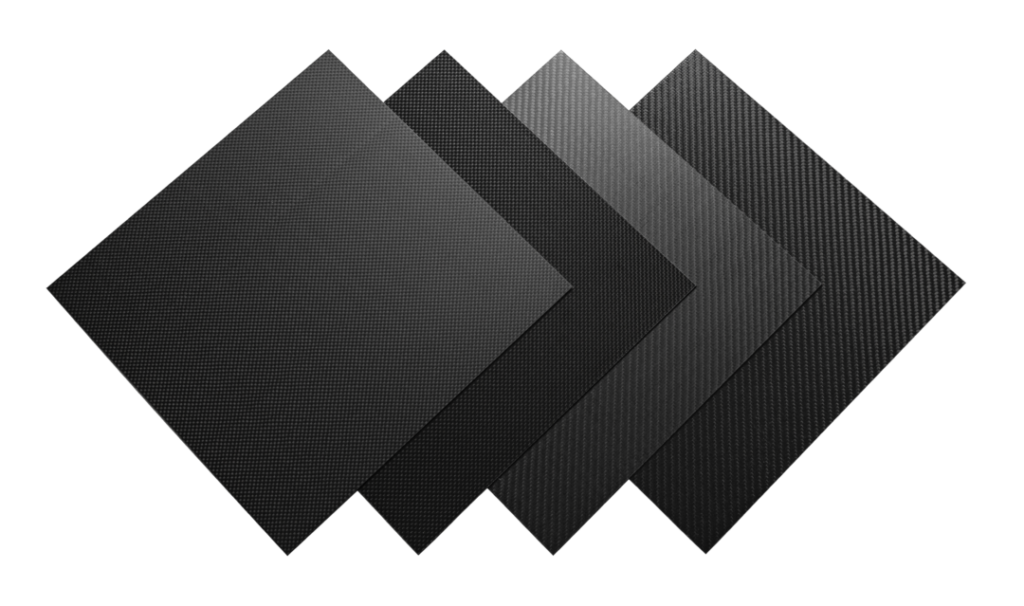

Carbon Fiber Surface Finishes Play a Role in Your Part Quality

There are so many options for manufacturing the surface finish on a carbon fiber panel. The surface finish you choose can make a difference in panel cost, and panel performance. The purpose of this is to explain the different surface finishes available from Elevated Materials, and when to use them.

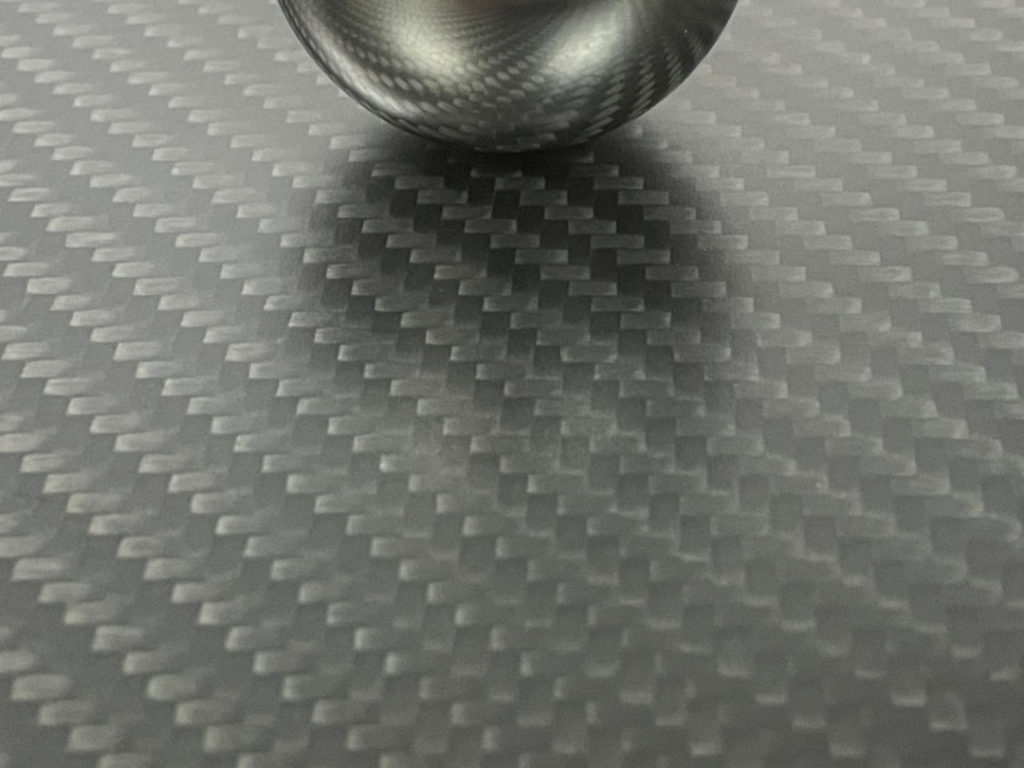

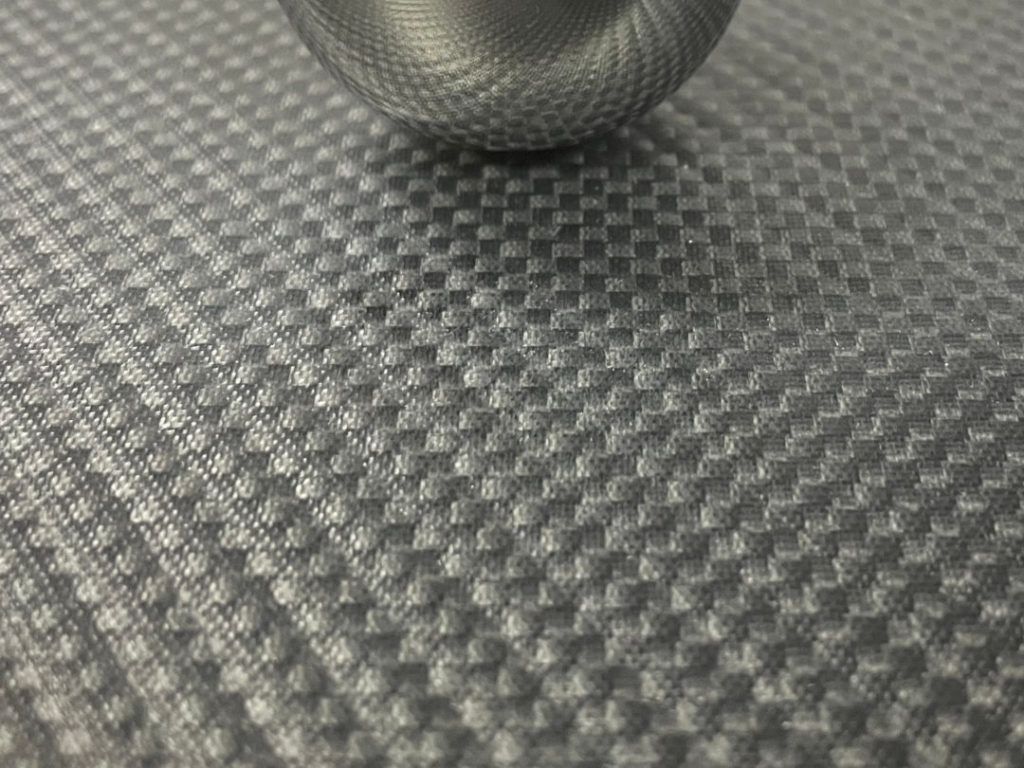

Matte Finish

This is a finish similar to what you would expect if you painted a matte clear coat onto your part. This finish is the Elevated Materials preferred finish and serves virtually every application well. The finish has very low to zero porosity. Paint and clear coat adhere well to this surface. Since this finish is created in a press, it can be put on both sides of a panel. This finish is also fairly durable and scratches picked up from use in your application don’t show up nearly as much as with gloss finishes. This finish also hides fingerprints that show up from handling parts. Matte finish panels are manufactured to stock at Elevated Materials.

Plain Weave Matte

Twill Weave Matte

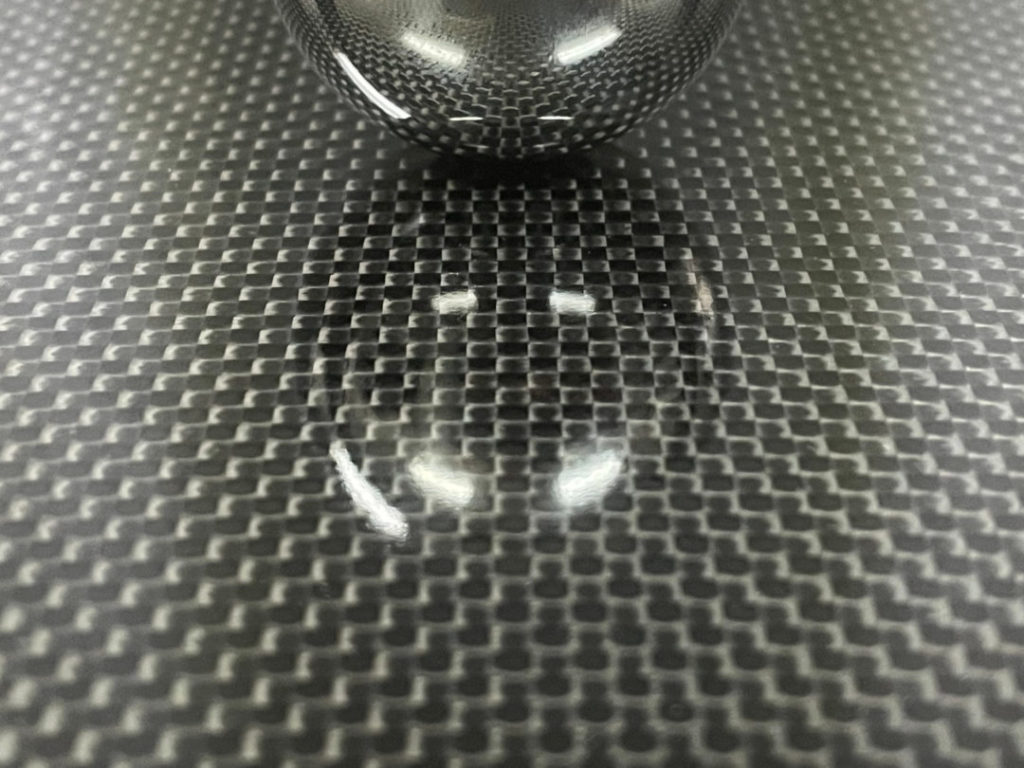

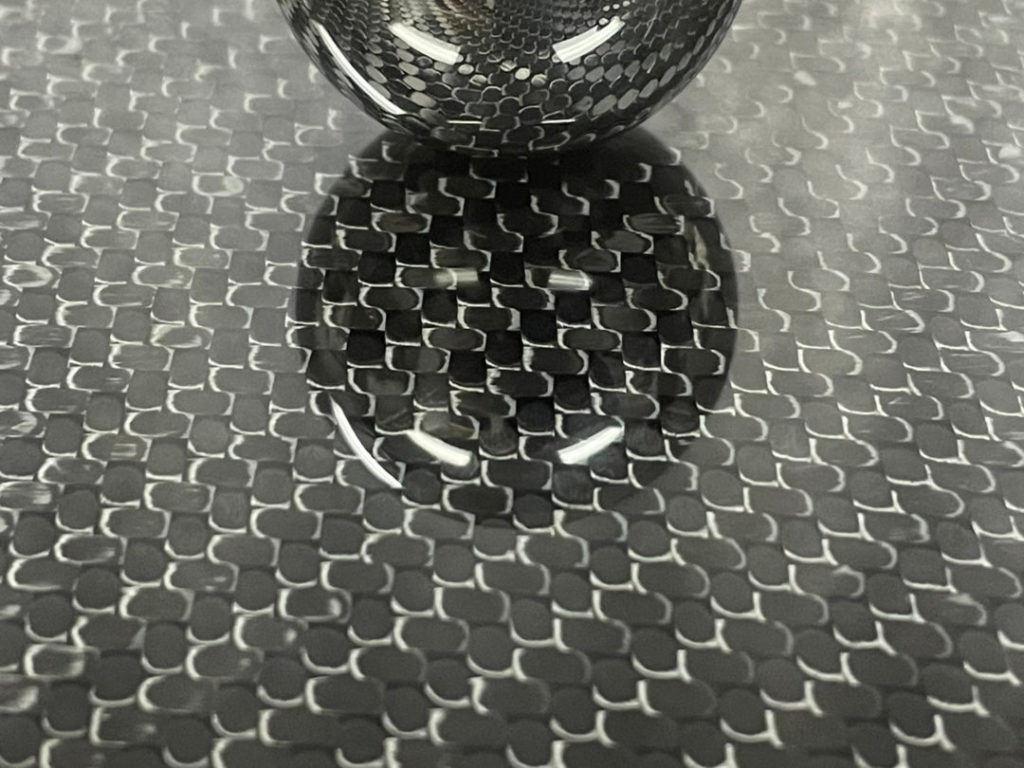

Gloss Finish

This is the smooth reflective carbon fiber look that most are familiar with. The gloss finish is great in cosmetic applications but shows many imperfections over time. Fingerprints and scratches will show up on this panel. This finish is only recommended in applications that don’t see constant use and where panels are not likely to be scratched. Since this finish is created in a press, it can be put on both sides of a panel. Gloss finish panels are made to order at Elevated Materials.

Plain Weave Gloss

Twill Weave Gloss

Peel Ply/Bond Prep

Various other manufacturers refer to this finish as a matte finish. We have chosen to identify this finish as a peel ply finish because it serves a specific purpose of preparing the laminate for applications where it needs to be bonded to something or something needs to be bonded to it. Panels with this finish come with a layer of peel ply attached to the panel and the peel ply must be removed to expose the bond prep surface. Since this finish is created in a press, it can be put on both sides of a panel.

Plain Weave Peel Ply

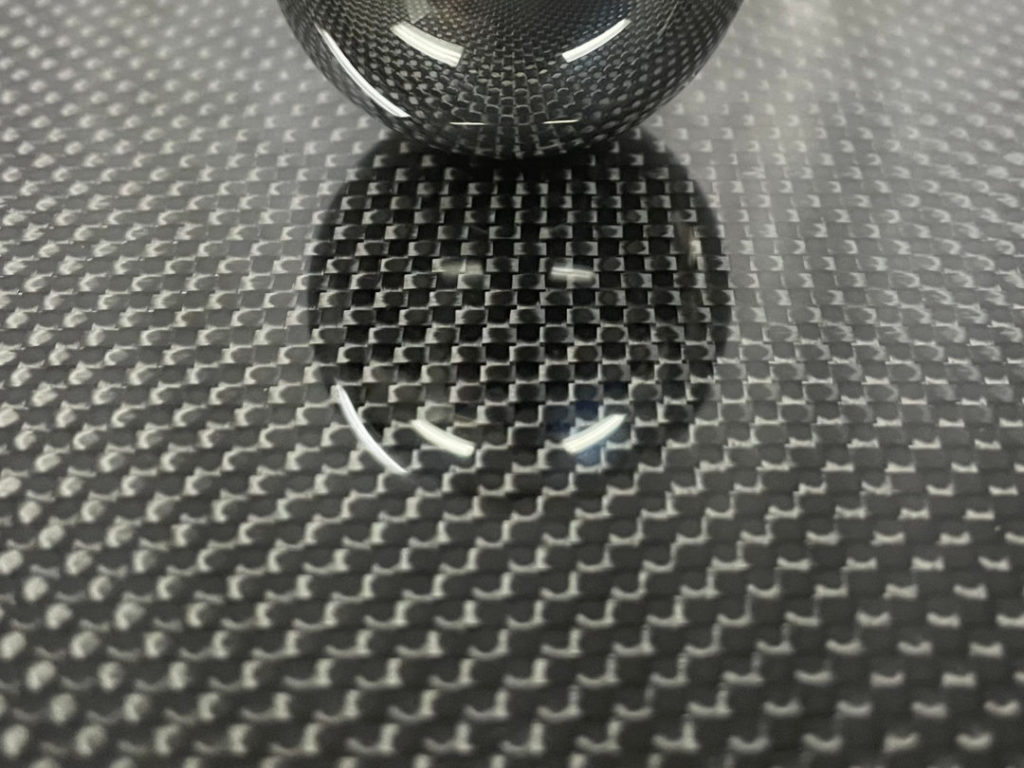

Vacuum Bag Finish – Gloss/Peel Ply

When resin infusing panels, a common process for manufacturing economy plates, fibers are laid against a glass surface. Resin is then pulled through the panel using vacuum. Using vacuum removes all air from the laminate and the panel is left with a glass smooth glossy surface when released from the glass. The surface is reflective and the fibers pop out visually.

While one side of the panel made using a resin infusion process is glossy from the glass plate used in laminations, the other side takes the finish of the vacuum bag. This leaves the surface rough and textured, following the pattern of the fibers in the fabric that was used. Resin infusion panels are best suited for applications where only one side of a panel needs to have a perfect cosmetic surface.

Vacuum Bag Gloss – Plain Weave

Vacuum Bag Peel Ply – Plain Weave

Vacuum Bag Gloss – 12K Twill Weave

Vacuum Bag Peel Ply – 12K Twill Weave