Our Services

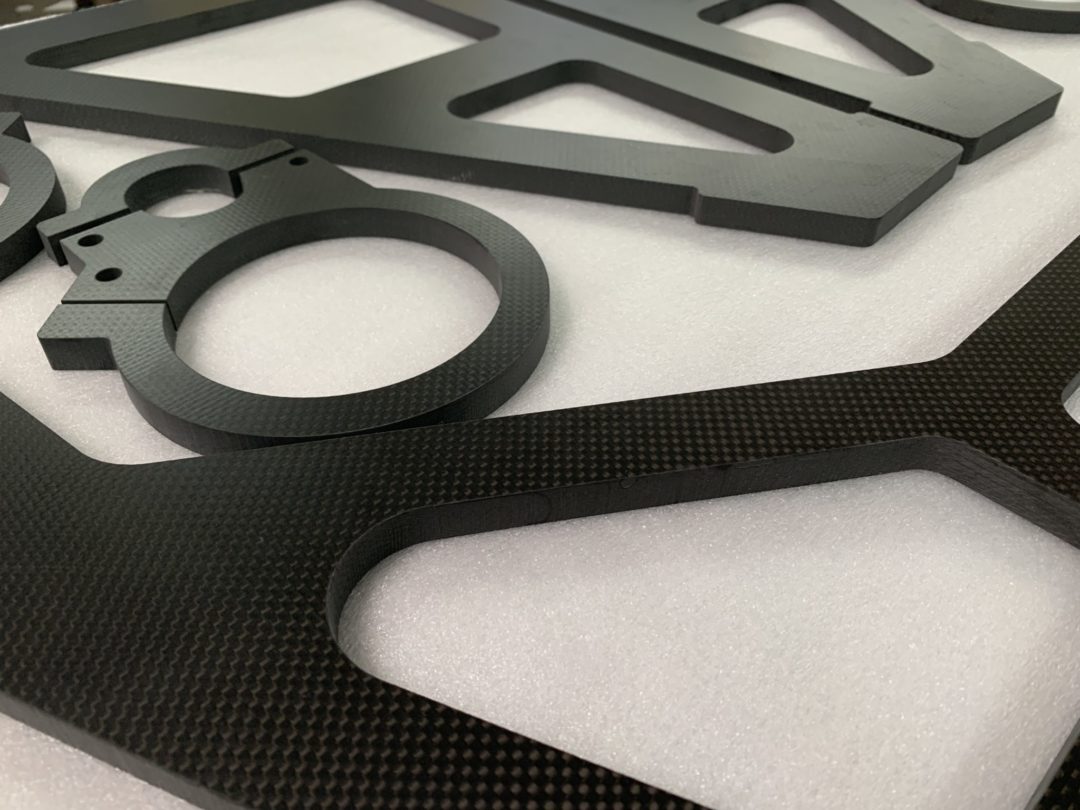

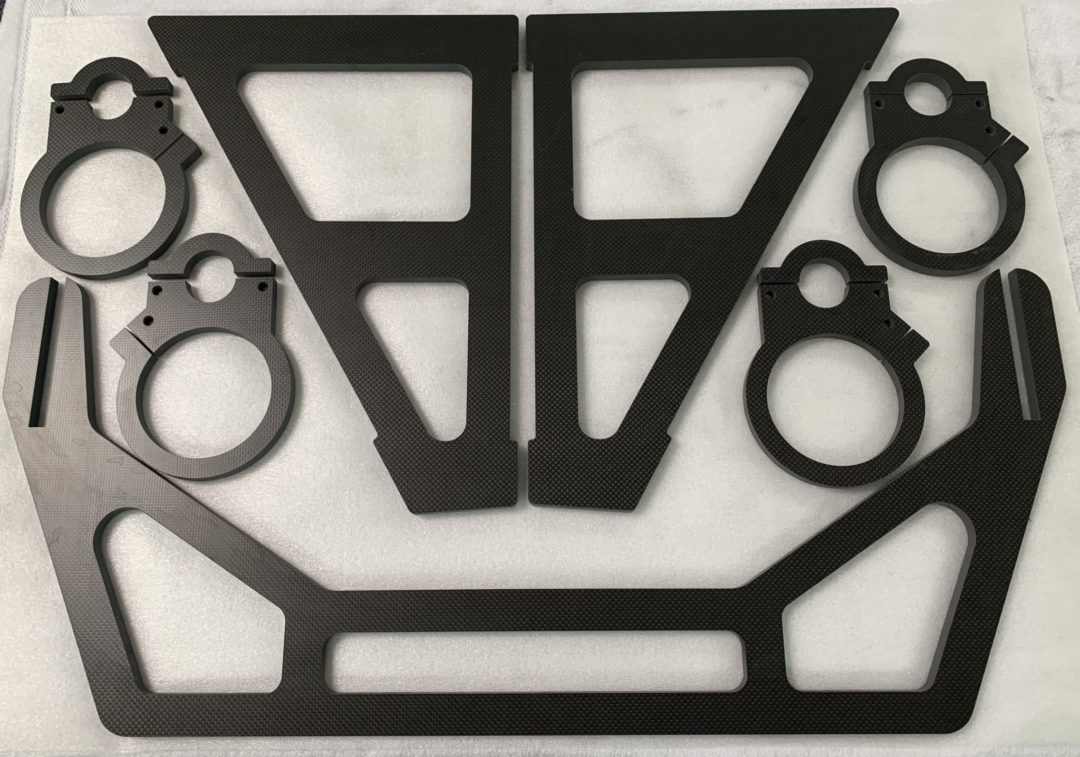

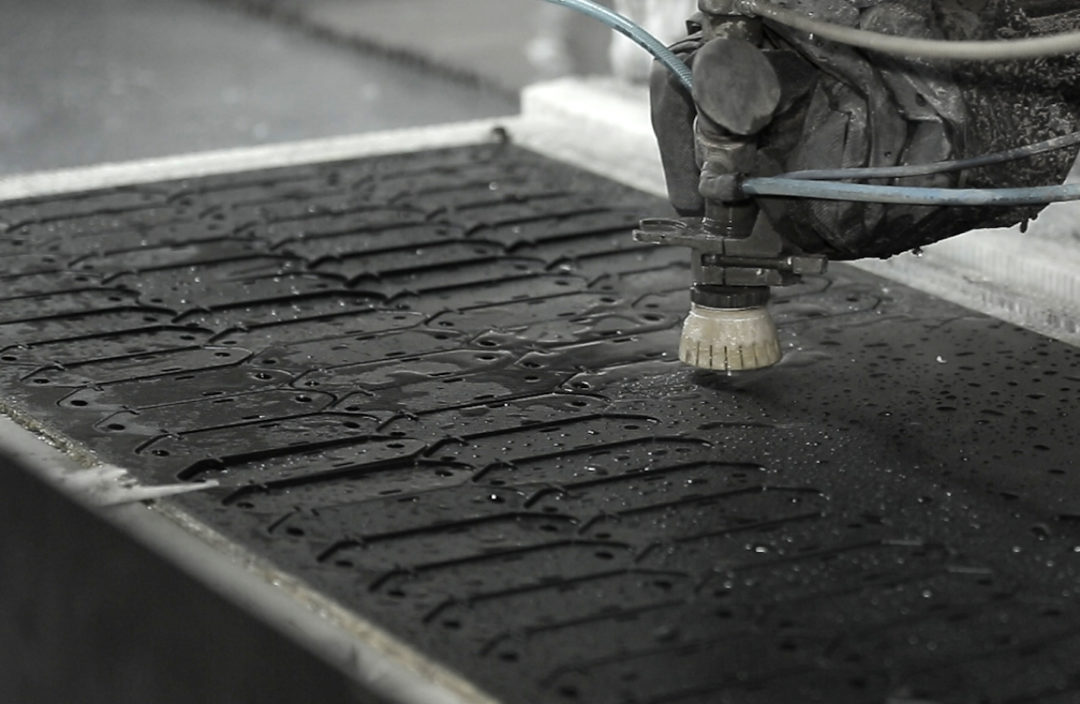

Waterjet Cutting

Our in-house Waterjet allows us to the cut the exact part or sheet you order. It's highly effective for perimeter cuts and interior cut-outs, especially for thicker material. Each part is carefully inspected with precision and accuracy both before and after the cutting process.

Specifications:

-

- 6' x 12' cut area

- No delaminations. Ever.

- Thicknesses range from 1/64" - 2"

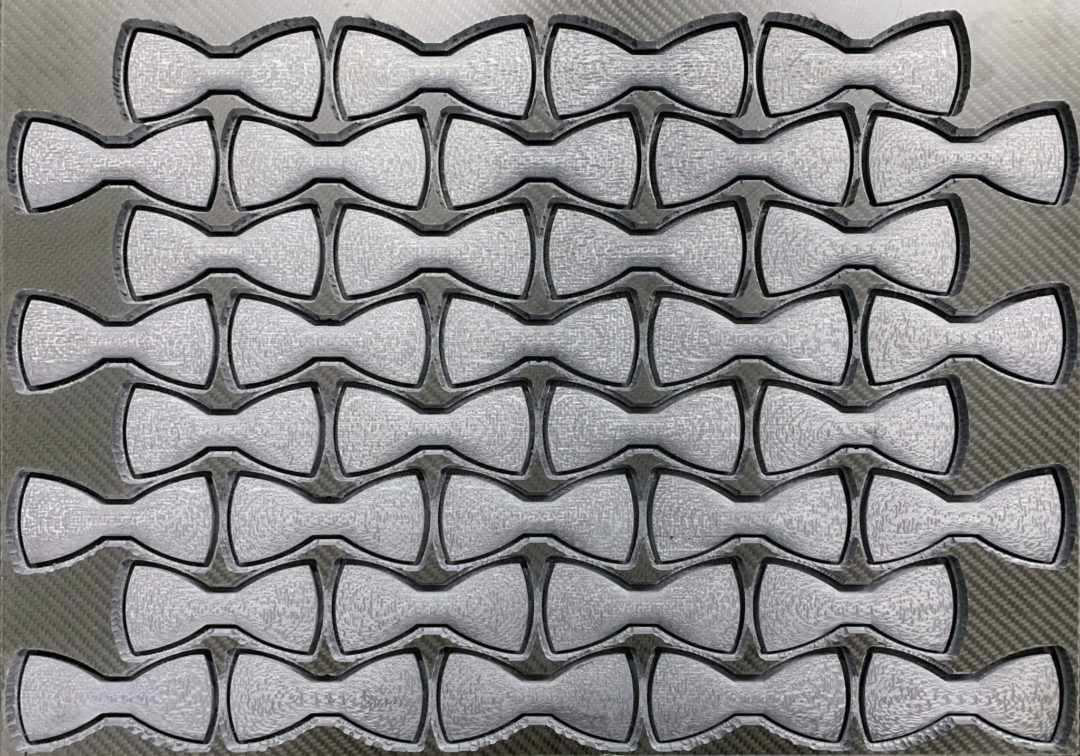

Carbon Fiber Machining

Our experience in machining carbon fiber using either a CNC router is unparalleled. The router at Elevated Materials is great for pockets, grooves or edge chamfers. Using a 3D model, provided by the customer, or designed by Elevated Materials, we can cut almost any type of feature accurately and precisely.

Specifications:

-

- Chamfers, 3D contours, fillets, and countersinks

- Sheets and plates: 2' x 3'

- Tubes: 24" long x 6" - 30" diameter

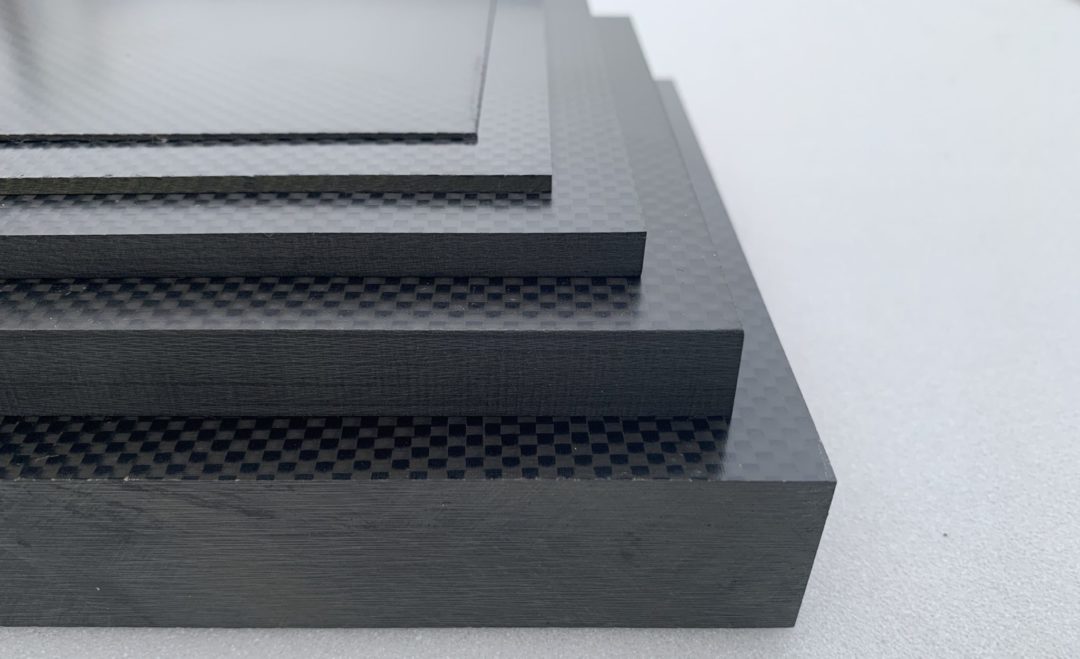

Custom Carbon Fiber Sheets

Our team can manufacture sheets to order depending on the application and type of material available. This includes quasi-isotropic layups, aluminum honeycomb panels, or sheets with a peel-ply on side. Custom thicknesses, sizes, and shapes are all possible with Elevated Materials.

Specifications:

-

- Dimensions range between 24" x 60" x 0.015" - 2+"

- Custom layups

- Multiple cosmetic weaves

Featured Projects

Let's discuss our manufacturing services!

Email: info@elevatedmaterials.com

Phone: (323) 391-1058

For inquires and custom quotes, please provide as much information as possible.